Application:

Rectifier Thyristor Technology as Eco Power Variant is used in electrolytic and surface-related processes, air-cooled high-current devices, and plasma applications.

Product Design:

Air-cooled (forced or convection) Thyristor-controlled rectifiers for high-current applications. The rectifiers are electronically controlled manually, via an interface (provided by the customer) or analog signals for constant voltage and current control. These rectifier units are thyristor also suitable for pole-changing processes such as degreasing or hard chrome plating.

Our Thyristor Technology is also available in synth. cooling, water-cooling and synth.-water-cooling.

Customer Benefits:

Optimized for output currents ≥ 2000 A, rectifier thyristor units oil-water cooling are especially preferred in demanding applications. The compact and service-friendly design complies with high industrial requirements and guarantees excellent process reliability.

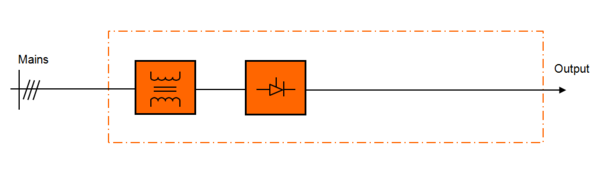

Block Diagram:

Technical Data:

| Mains Voltage: | 3 x 400 V / 50 Hz + N + PE |

|---|---|

| Output Current: | > 1000 A up to 15000 A |

| Output Voltage: | 6 V up to 150 V |

| Ripple: | approx. 5 % full range |

| Duty Factor: | 100 % (24/7) |

| Efficiency: | 80 % to 93 % |

| Ambient Temperature:: | + 35 °C > + 40 °C (Option) |

| Protection Grade: | IP 54 tank / IP 23 cover |

Drawing:

Project-related

Interfaces: