Application:

In modern electroplating plants Central Multi Circuit power supplies are found very often. The PowerCabinet – Nano rectifiers in low-floor design are used for POP (plating on plastic) and for zinc as well as zinc nickel processes.

Product Design:

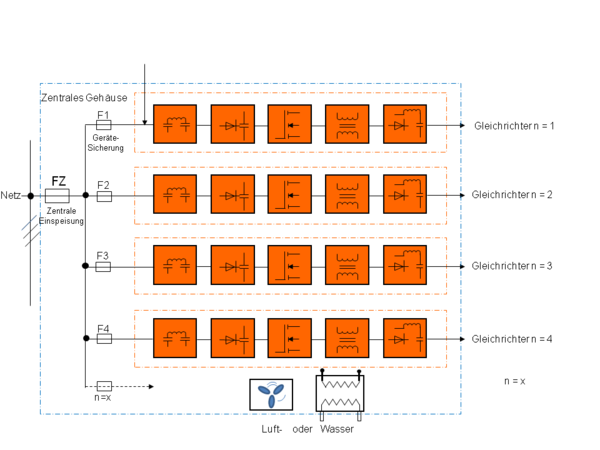

The PowerCabinet-Nano can consist of 6 individually controllable outputs, 16 V / 1500 A each.

Power Cabinet – Nano rectifiers are characterized by a constant low ripple of < 1 % – 3 %. The rectifier units are integrated in one central cabinet which reliably supplies the entire galvanic tanks with direct current and provides an excellent protection to the power circuits. Installed with a central feed-in this system offers the security-related selectivity and the communication-related components as well as the cooling concept. Cooling and circuit risks at the galvanic tank are therefore ruled out.

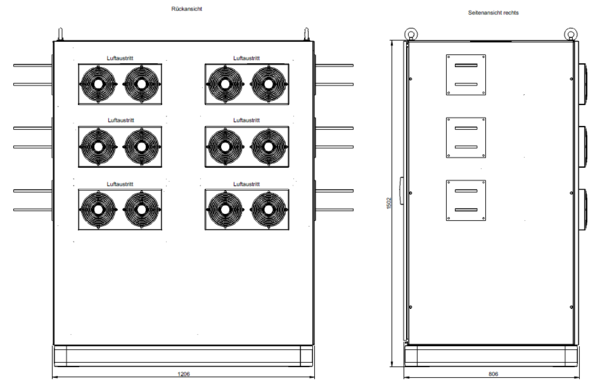

The PowerCabinet Nano is available in both air-cooled and water-cooled versions. Regarding the interfaces please have a look at our Multi-Circuit Power Supplies.

If height is a challenge please take a look at our water cooled rectifier PSP 2540 in low-floor design.

Block Diagram:

Customer Benefits:

The compact design of the PowerCabinet Nano offers a sustainable and robust solution for demanding electroplating environments. It effectively counters corrosive ambient conditions at the tanks and ensures maximum operational safety.

Thanks to modular rectifier technology, the PowerCabinet Nano provides an ideal balance of accessibility, flexibility, safety, and reliability-all in one central system.

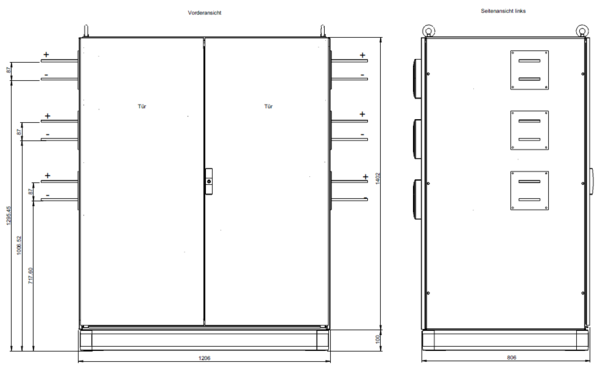

Drawing:

| Mains Voltage: | 3 x 380 – 480 V / 50 – 60 Hz |

|---|---|

| Duty Factor: | 100 % |

| Ambient Temperature: | up to + 35 °C |

| Protection Grade: | IP 54 |

| Colour: | RAL 7035 |

| Dimensions: | B/T/H: 1200/800/1400 [mm] |

Interfaces: