Hard anodizing requires flexible solutions

The HS 1200 has been especially developed for hard anodizing different aluminum alloys. The process controller allows easily setting complex sequential programs, monitoring the current process and logging the process data. The program editor helps you to keep track of your process any time. The current, voltage and temperature process variables are not only displayed as numerical values or bars but also as trend lines. This way, you do not only know what comes next, but also see online what has happened already.

The industrial touch panel provides the robustness required at the process tank while the compact design allows the HS 1200 to be installed almost anywhere.

HS 1200 Process Controller

Hard anodizing of aluminum mainly requires high flexibility when configuring anodizing programs. Owing to the large spectrum of alloys and wide range of electrolytes, optimum results can only be achieved by means of a process controller providing maximum flexibility. With its 200 multi-step programs, the HS 1200 offers clear and easy operation and more versatility. Pulse function, surface mode function and other additional functions allow individual program sequences for better results and higher productivity. A special program editor ensures clarity during programming. The graphics-enabled color touch panel supports intuitive operation.

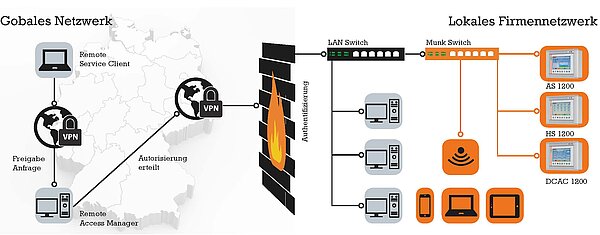

The digital interface facilitates the integration of the device into a modern Ethernet-based network. This ensures flawless data exchange between production and order management.

Optional functions allow for an online production control via digital interface not only at the PC but also on mobile devices.

More power in an even smaller space – this is another feature of the HS 1200 compared to the successful previous generation. Hardly bigger than the 9” screen, the HS 1200 control can be installed almost everywhere.

Main Features

Block diagram

IoT / Industry 4.0

Do you always like to know how many loads you have already produced today? Would you like to supply your customer with a production log when delivering the goods?

The HS 1200 control supports your move toward Industry 4.0 with a proven Ethernet interface and optional mobile and remote access capabilities. Secure communication enables real-time data transfer—from the process tank directly to your customer’s system.