Application

Thyristor rectifier units, water-cooled are used in aluminium anodizing, electrolytic brightening, electrolysis, galvanic high-current applications, strip refinement, and pulse applications.

Product Design

Especially in the fields of high-current processes water cooling has become established. As a cooling medium, water is considerably better at achieving a high packing density. The well-proven Thyristor Technology combines wear-free capacity adjustment and dynamic process developments. A power supply system which can be integrated individually in any plant concept.

Our thyristor rectifier units is also available in synth. cooling, synth.-water-cooling and air-cooling.

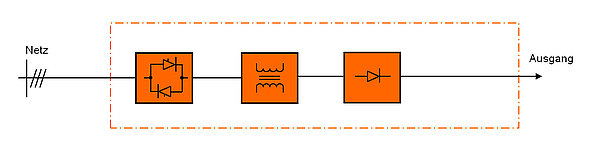

Block Diagram

Functional Description

Capacity adjustement is achieved either on the primary side or on the secondary side of the device. Using a power switch or fuse elements and main contactor ensures safe mains separation. Galvanic mains separation is achieved by the main transformer. A 6-pulse rectification meets the requirements which are relevant to the process. By means of additional smoothing elemnts almost all desired ripples can be realized. All main components such as semiconductors, transformer, bars are being cooled which enables a high packing density.

Customer Benefits

MUNK Thyristor Technology in water cooling is perfected to the special needs in power conversion and is particularly recommended for high-power applications or when size matters. Cooling a rectifier by means of water is most efficient because the water is recycled in a cooling loop and can be re-used for cooling the most powerful rectifiers even if the ambient temperature exceeds 40 °C.

Technical Data

| Mains Voltage: | 3 x 400 V / 50 Hz + N + PE (+all usual mains voltages or 60 Hz) |

|---|---|

| Output Current: | 1.000 A up to 100.000 A |

| Output Voltage: | 6 V bis 900 V |

| Ripple (standard): | approx. 5 % at full load |

| Ripple (option): | 2 – 3 % at full load |

| Duty Factor: | 100 % (24/7) |

| Efficiency: | 80 % up to 93 % |

| Ambient Temperature: | + 35 °C + 40 °C (Option) |

| Cooling: | Water |

| Water inlet temperature: | + 16 °C up to + 35 °C |

| Protection grade: | IP 54 |

Drawing

Project-related

Interfaces