Application

Thyristor rectifiers are ideal for electrolytic and surface-related processes as well as for air-cooled high-current devices and plasma processes.

Product Design

A highly robust thyristor-based adjustment system, available as air self-cooled or external air-cooled version (for high-current applications). The units are compact and universally applicable. Depending on the process, it can be controlled by constant current or voltage, manually or via a customer-specific interface. Due to the electronic adjustment, certain pulse applications are also possible. Thyristor technology is also used for polarity reversal processes such as degreasing or hard chrome.

Our thyristor technology is also available as synth. cooled, water-cooled and synth.-/water-cooled variants

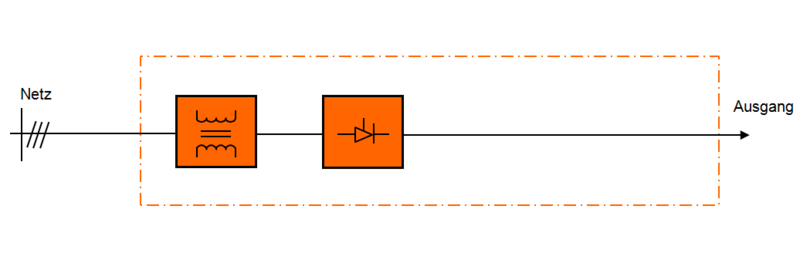

Block diagram

Customer benefits

Thyristor technology is popular in the medium power range ≥ 2000 A. It is easy to handle, reliable in harsh industrial environments, and straightforward when it comes to service and maintenance.

For these reasons, thyristor-based systems enjoy a high level of trust among industrial users.

Technical Data:

| Mains voltage: | 3 x 400 V / 50 Hz + N + PE (+all common mains voltages or 60 Hz) |

|---|---|

| Current output: | 1000 A – 15000 A |

| Output voltage: | 6 V – 900 V |

| Ripple (Standard): | approx. 5 % at full modulation |

| Ripple (Option): | 2 to 3 % at full modulation |

| Duty cycle: | 100 % (24/7) |

| Efficiency: | 80 % – 93 % |

| Cooling: | Air |

| Ambient temperature: | + 35 °C + 40 °C (Option) |

| Protection class (Standard): | IP 20 – IP 23 |

| Protection class (Option): | > IP 23 |

Dimension drawing

project-related

Interface