Smart – Fast – Efficient – Reliable

The AS 1200 is an intelligent and high-performance process controller specifically designed for decorative anodizing applications. With closed-loop control, automatic monitoring, and integrated data logging, the AS 1200 increases productivity, ensures process reliability, and minimizes errors.

Thanks to its optimized current density control mode, the AS 1200 support you to reach target layer thickness faster and more precisely—resulting in consistently high quality, fewer reworks, and greater efficiency in your anodizing line.

AS 1200 Process Controller

Simplified, intuitive operation and increased productivity are only two of the essential advantages the AS 1200 offers. The control algorithm optimized to the needs and requirements of decorative anodizing guarantees shortest process times. The industrial graphics-enabled touch panel supports intuitive operation. Additional process information is displayed as numerical values and trend lines on the screen.

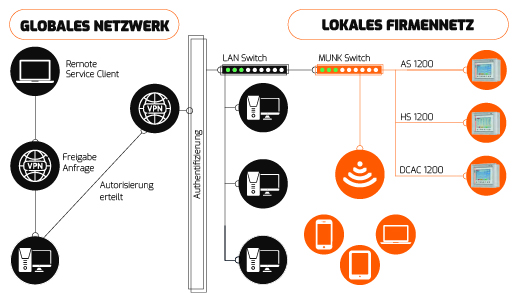

The digital interface facilitates the integration of the device into a modern Ethernet-based network. This ensures flawless data exchange between production and order management.

Optional functions allow for an online production control via digital interface not only at the PC but also on mobile devices.

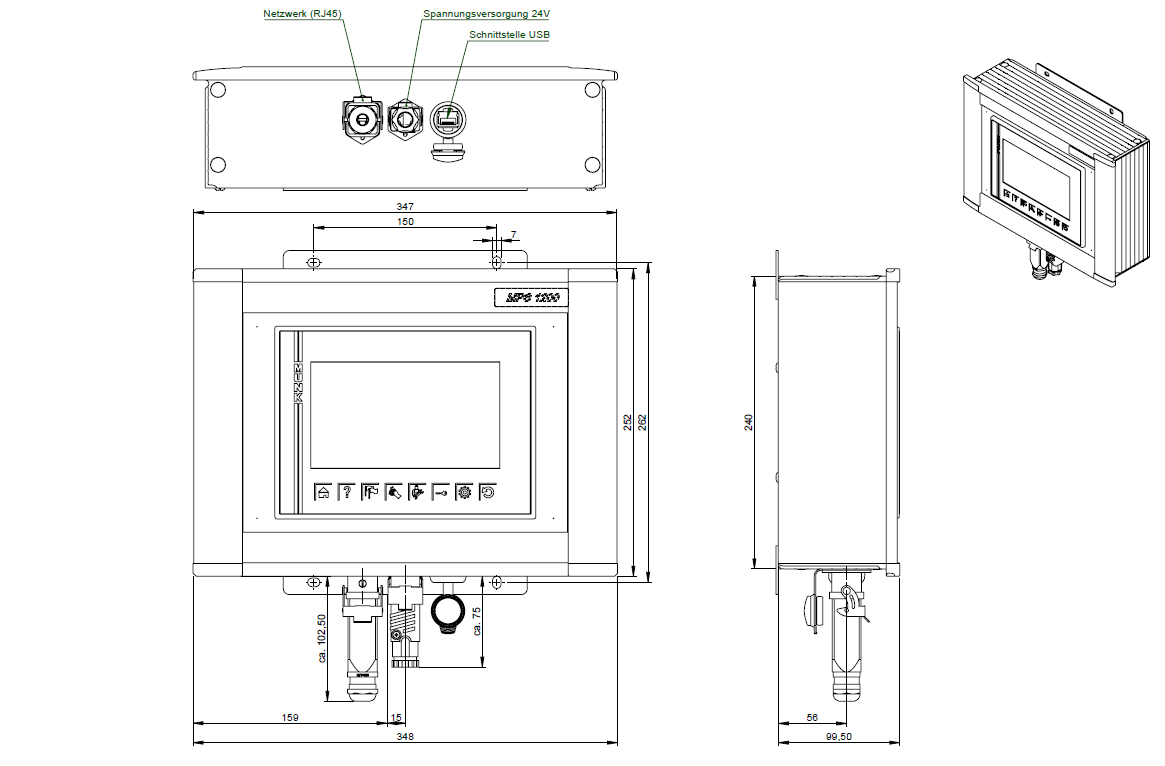

More power in an even smaller space – this is another feature of the AS 1200 compared to the successful previous generation. Hardly bigger than the 9” screen, the AS 1200 can be installed almost everywhere.

Main Features

MUNK Gateaway

Dimensional drawing

IoT / Industry 4.0

Do you always like to know how many loads you have already produced today? Would you like to supply your customer with a production log when delivering the goods?

The AS 1200 supports your journey towards loT and Industry 4.0 with its proven Ethernet interface and optional remote access features. Secure, real-time data transfer from the process tank to your customer’s system has never been easier.